SCB Drive

Galvanometer-Scanner

made in

Germany

SCB Drive

Galvanometer-Scanner

made in

Germany

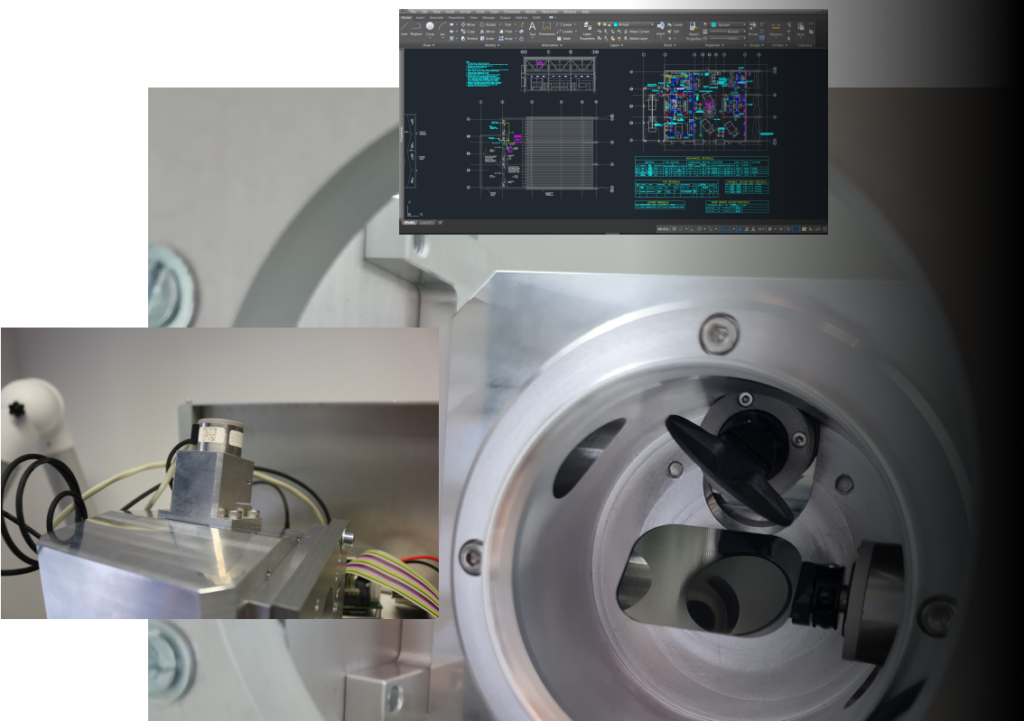

Discover the future of laser marking with SUCABO. Our innovative strength and expertise enable precision, speed and reliability at the highest level.

As an environmentally conscious company, SUCABO stands for the efficient use of resources in our manufacturing processes and the sustainable use of renewable energies.

At SUCABO, we lead the way with a pioneering spirit to create forward-looking manufacturing solutions and shape the industry of tomorrow.

SUCABO proudly manufactures in Germany. Our location stands for the highest reliability and quality – values that can be felt in each of our products.

Precision, reliability, excellence – at SUCABO, quality and performance are inextricably linked. Discover Galvoscanners that set the highest standards.

More than just one

area of application

More than just one

area of application

Thanks to its sophisticated mechanical design, the SCB Drive allows you to handle even the most complicated applications.

Additive Manufacturing

Laser additive manufacturing revolutionizes production through precise layer-by-layer application and fusion of material. This enables complex designs, reduced material usage, and accelerated prototyping in industries such as aerospace, medical, and automotive.

In order to provide our customers with maximum dynamics and optimal laser spot at the same time, we have designed our SCB Drive for 20/30 mirror apertures. As a result, workpieces with the highest dimensional accuracy can be achieved.

Micromachining

Micromachining using laser radiation refines manufacturing processes on a tiny scale. Through targeted material removal or modification, it enables the production of complex microstructures for electronics, medical technology and more.

During the development of the SCB Drive, we placed particular emphasis on the highest possible and constant drift throughout the entire working field. In this way, we enable users to realize even the finest structures at the machining edges.

Laser Marking

Laser marking is defined by precise, non-contact marking of materials using laser beams. This ensures permanent, high-resolution markings in industries such as electronics, medicine, and automotive. The method is characterized by high flexibility and environmental friendliness.

SUCABO relies on Galvoscanners with digital encoders. The associated high precision and minimal drift help our customers to handle even large-scale marking tasks with reliable accuracy.

Additive Manufacturing

Laser additive manufacturing revolutionizes production through precise layer-by-layer application and fusion of material. This enables complex designs, reduced material usage, and accelerated prototyping in industries such as aerospace, medical, and automotive.

In order to provide our customers with maximum dynamics and optimal laser spot at the same time, we have designed our SCB Drive for 20/30 mirror apertures. As a result, workpieces with the highest dimensional accuracy can be achieved.

Micromachining

Micromachining using laser radiation refines manufacturing processes on a tiny scale. Through targeted material removal or modification, it enables the production of complex microstructures for electronics, medical technology and more.

During the development of the SCB Drive, we placed particular emphasis on the highest possible and constant drift throughout the entire working field. In this way, we enable users to realize even the finest structures at the machining edges.

Laser Marking

Laser marking is defined by precise, non-contact marking of materials using laser beams. This ensures permanent, high-resolution markings in industries such as electronics, medicine, and automotive. The method is characterized by high flexibility and environmental friendliness.

SUCABO relies on Galvoscanners with digital encoders. The associated high precision and minimal drift help our customers to handle even large-scale marking tasks with reliable accuracy.

SCB Drive

The SCB Drive impresses with its outstanding precision, dynamics and reliability. This makes it the optimal choice for a wide range of applications.

Precision is our trademark. SUCABO stands for accuracy and attention to detail in every aspect.

At SUCABO, we drive innovation to create game-changing manufacturing solutions that shape the industry of tomorrow.

We proudly bear the label „Made in Germany“. Our products combine German engineering and the highest quality standards.

SUCABO focuses on sustainable production through efficient use of resources and environmentally friendly technologies, for a responsible future.

The Team

SUCABO combines the expertise of three engineers with many years of experience in various subject areas of the industry. Our shared passion and extensive experience have shaped the SCB Drive – a top-of-the-line product that combines precision and robustness.

Fabian Suttner

Fabian Suttner

Pietro Caltabiano

Pietro Caltabiano

David Filser

David Filser

FAQ

SUCABO’s Galvoscanners are characterized by impressive precision, high speed and exceptional reliability. With advanced mechanics and dynamic capabilities, it offers a wide range of applications in laser marking and material processing.

Our Galvoscanners are proudly developed and manufactured in Germany. Thanks to our local production, we offer our customers not only first-class quality and precision, but also a secure source of supply within Europe. This is the optimal protection against political uncertainties and potential challenges in global supply chains. We work closely with companies that are both local and have a long tradition and excellence in manufacturing. In doing so, we rely on strong partnerships to guarantee our customers the highest level of reliability and first-class service.

Yes, the SCB Drive has been designed with great versatility to be compatible with various applications. We understand that every customer has unique requirements. We are therefore not only willing to adapt our Galvoscanners to your existing machines, but we are also happy to tackle small development projects to ensure that the SCB Drive is the best fit for your specific needs. Your satisfaction is our top priority, and we provide you with the flexibility you need to get the most out of our capabilities together.

Our Galvoscanners have an open sensor interface. As a result, our customers enjoy maximum freedom in the choice of a control solution.

For optimal use of the SCB Drive, we recommend specially developed electronics. In close cooperation with our partner SCAPS, a control board was created that is perfectly matched to the requirements of the SCB Drive.

The advantage of this kit is that it allows for a smooth integration of the SCB Drive into your machine without having to worry about extensive developmental effort. The kit is carefully designed to ensure the highest precision and optimal performance.

If you are interested in a fully developed kit or if you have any further questions about the integration of the SCB Drive into your machine, please do not hesitate to contact us. Get in touch with us for detailed information and find out how easy it is for you to benefit from our tuned kit solution.

The optimal performance, precision and durability of a Galvoscanner is critically influenced by the way it is mounted in a scanner. Both the mechanical and thermal conditions must be carefully checked during integration.

We deliver our Galvos with custom-made and electrically insulating thermal conductive foils and advise you on all necessities, such as the selection of the required clamping forces. Additinally, we are flexible and can adapt to existing applications on request. Whether additional cooling capacity or special adaptations are required for specific applications, we are here to help.

Get in touch with us

We are here for your questions, inquiries and interests in products and services. Our team is ready for you.